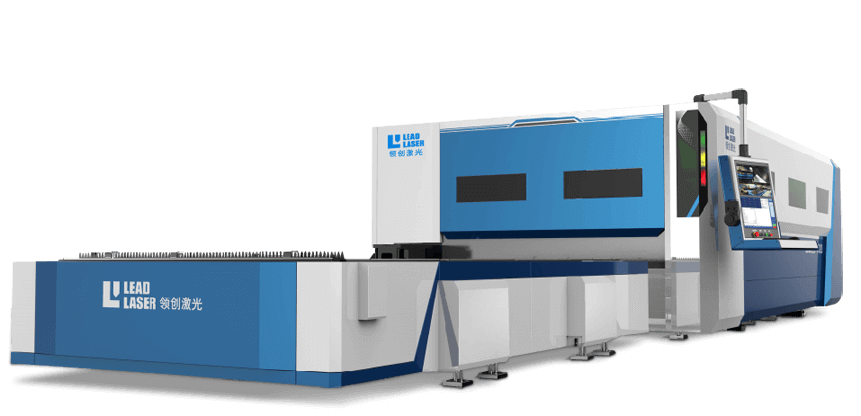

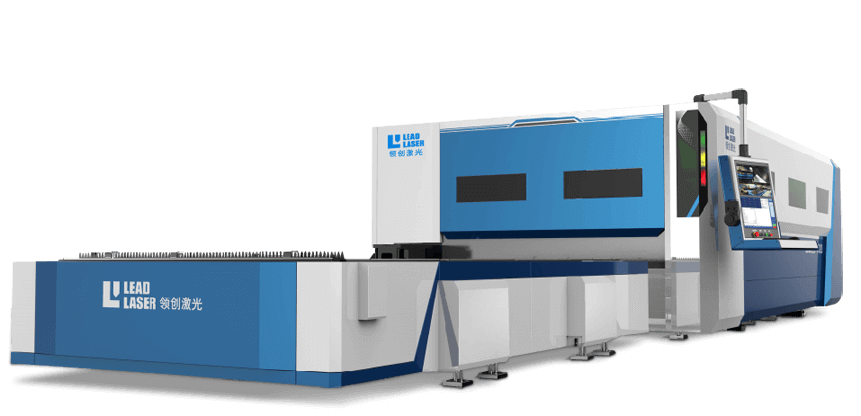

Lead Laser LR-4020

Lead Laser LR-4020

Leading Laser Cutting Flatbed Machine Model: LR-4020 Equipped with Raycus 6000W Power Laser Generator

1. Equipped with German KEBA intelligent operating system, after secondary development and application, it can realize a variety of laser-specific functions, and the operation interface is simpler and more convenient.

2. The beam adopts thin-plate welded steel beam technology, which improves the rigidity of the beam and reduces the weight of the beam. The Z-axis adopts a compact structure design, which shortens the volume of the Z-axis. The cover is welded with aluminum plates, which greatly reduces the weight of the Z-axis.

3. The exchange table adopts hydraulic lift. Four groups of oil cylinders move synchronously and vertically lift, which shortens the exchange time of the two worktables of the machine tool and improves the working efficiency of the machine tool. The output force of the hydraulic cylinder is extremely high, and four sets of cylinders can lift a workpiece of 20 tons, which is 2.5 times that of the mechanical exchange table, which can meet the requirements of thick plate cutting for high-power laser cutting machines.

4. The base cutting area and the cutting box are made of refractory materials to cover the metal bed on the upper surface, which can protect the machine bed from being damaged by the laser during high-power laser cutting, and improve the service life of the machine tool.

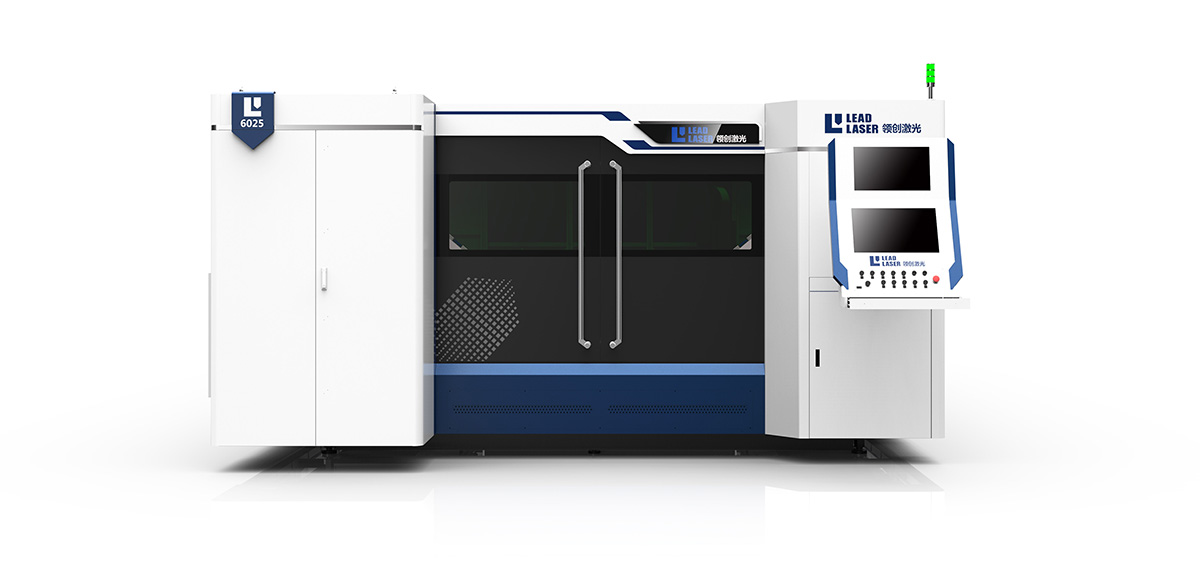

Lead Laser LEAD-4020

Lead Laser LEAD-4020

LEAD Laser Cutting Flatbed Machine Model: LEAD-4020 Equipped with Raycus 3000W Power Laser Generator

1. Equipped with German KEBA intelligent operating system, after secondary development and application, it can realize a variety of laser-specific functions, and the operation interface is simpler and more convenient.

2. The beam adopts thin-plate welded steel beam technology, which improves the rigidity of the beam and reduces the weight of the beam. The Z-axis adopts a compact structure design, which shortens the volume of the Z-axis. The cover is welded with aluminum plates, which greatly reduces the weight of the Z-axis.

3. The exchange table adopts hydraulic lift. Four groups of oil cylinders move synchronously and vertically lift, which shortens the exchange time of the two worktables of the machine tool and improves the working efficiency of the machine tool. The output force of the hydraulic cylinder is extremely high, and four sets of cylinders can lift a workpiece of 20 tons, which is 2.5 times that of the mechanical exchange table, which can meet the requirements of thick plate cutting for high-power laser cutting machines.

4. The base cutting area and the cutting box are made of refractory materials to cover the metal bed on the upper surface, which can protect the machine bed from being damaged by the laser during high-power laser cutting, and improve the service life of the machine tool.

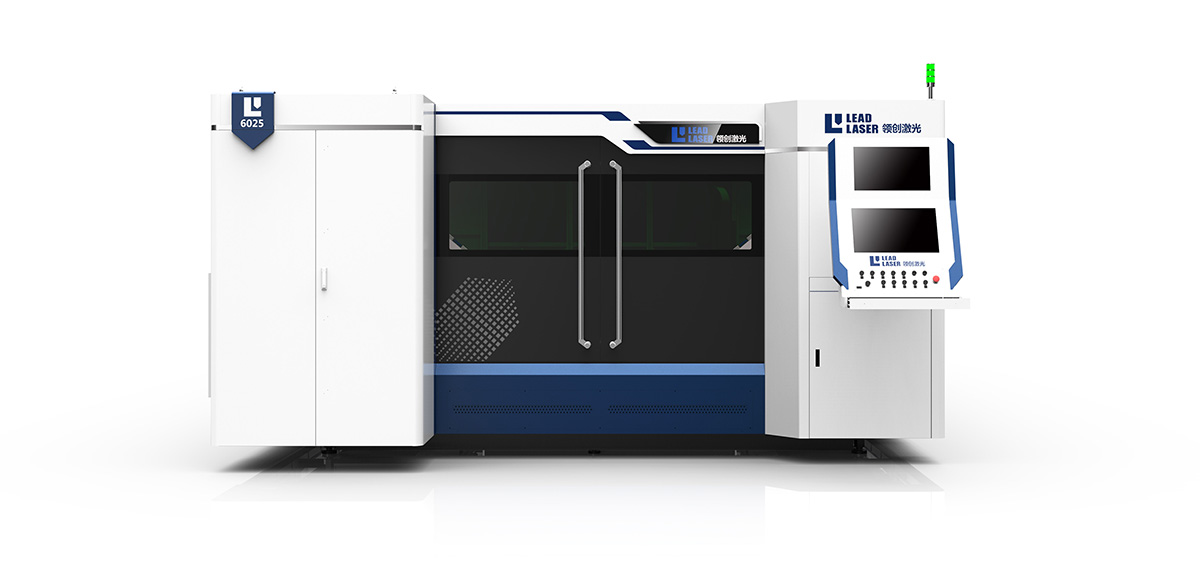

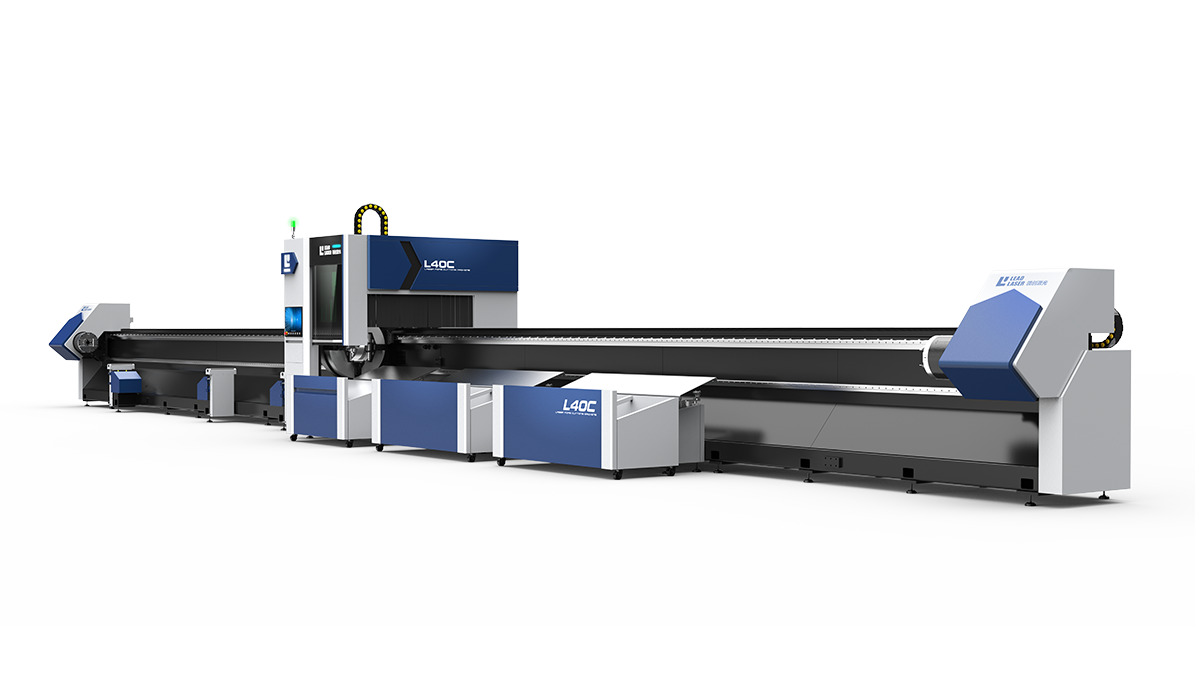

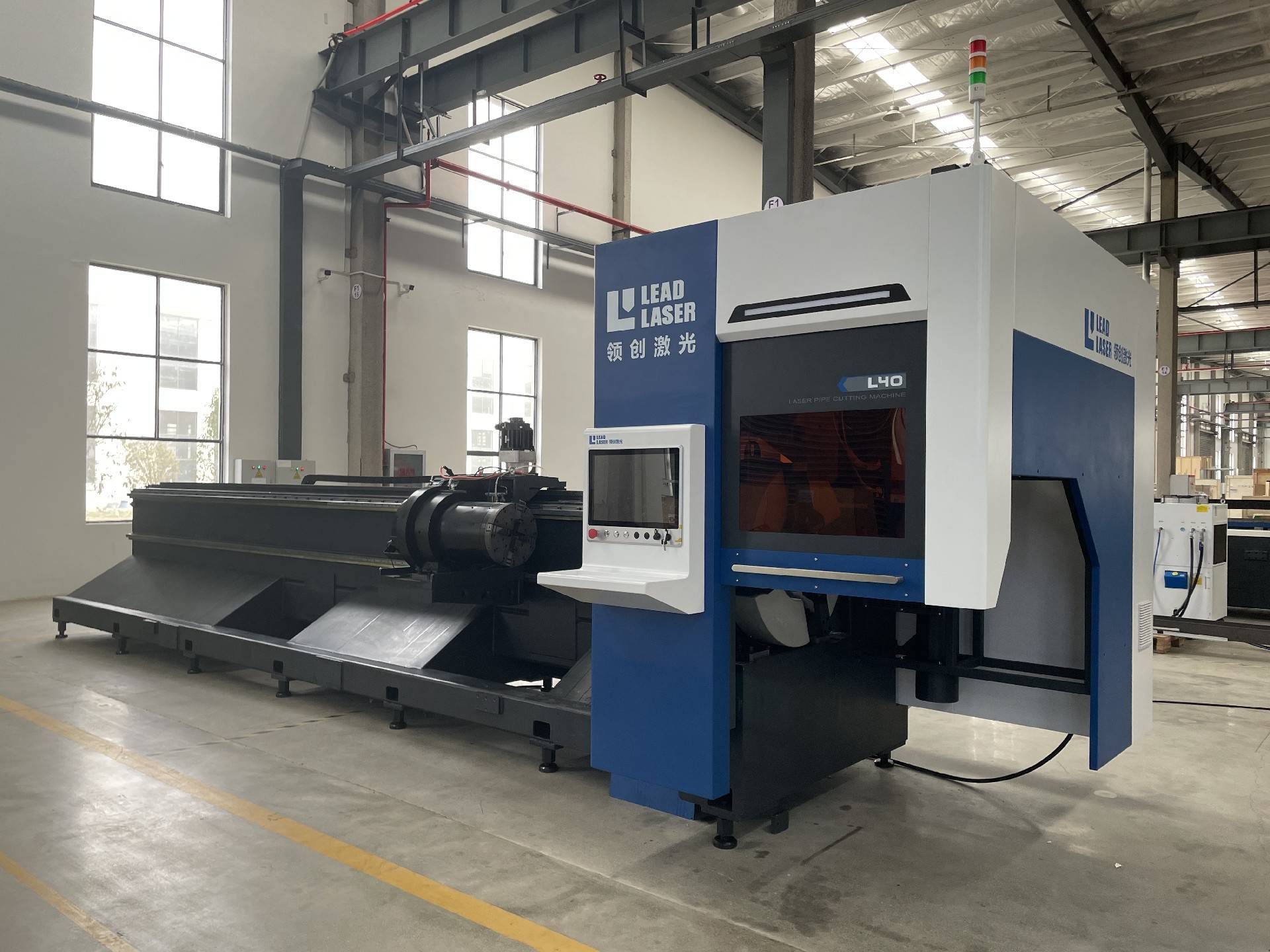

Lead Laser VF-6520

Lead Laser VF-6520

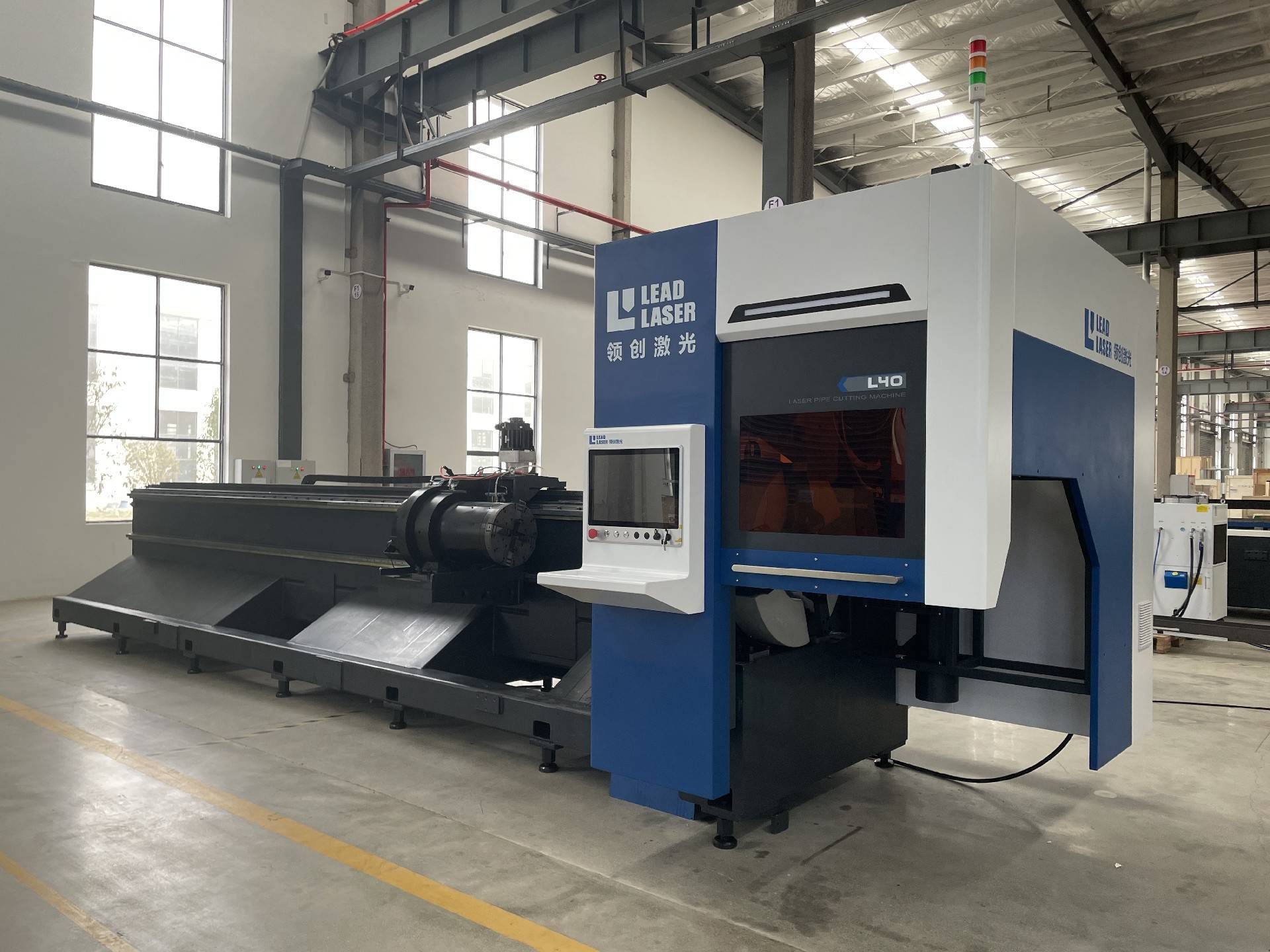

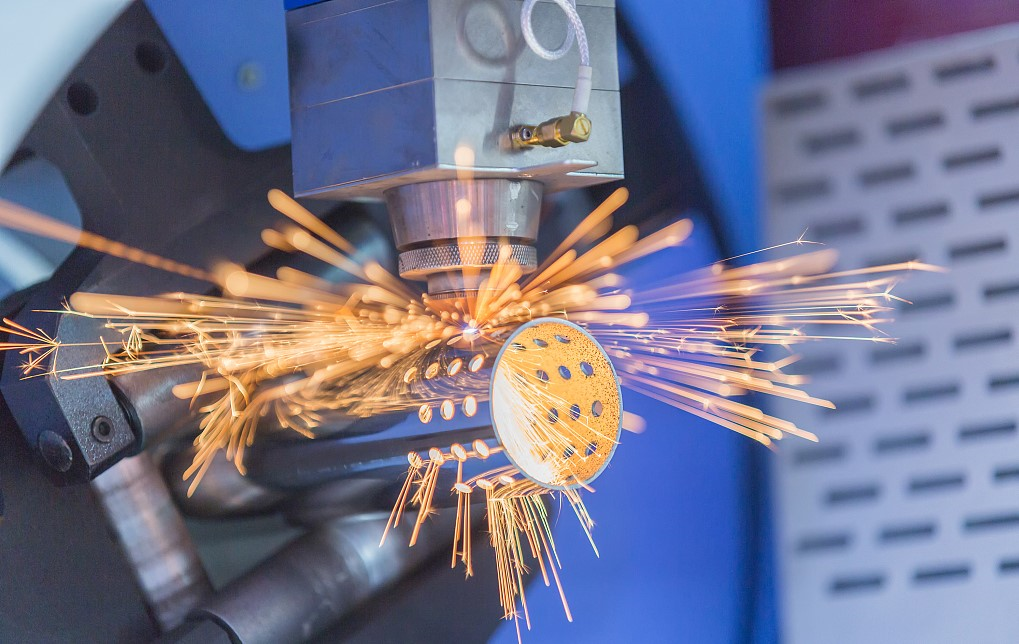

1. The L series laser cutting machine adopts the special flying optical path structure model for cutting pipes, adopts the finite element technology with independent technology property rights and the beam and base with cantilever structure with high bearing capacity, and eliminates stress by heat treatment to achieve strength, rigidity and servo. Drag acceleration and deceleration are highly matched with the CNC system. The equipment has sufficient rigidity, excellent reliability and high-efficiency cutting performance.

2. Equipped with a dedicated laser bus system and Japanese YASKWA servo motors, the high-precision coupling is perfectly matched to ensure the stability of the control. The operation is convenient and easy to use, and you can learn it on the same day.

3. High-precision chuck: long-term use can maintain the center repeat positioning accuracy of 0.05mm; the double-roller clamping design structure can reduce pipe shaking and improve cutting accuracy.

4. High flexibility: The clamping force adjustment accuracy is ±1.0kg, and the clamping force is highly controlled for thin-walled pipes, avoiding deformation of pipe clamps.

5. Green and environmental protection: the sealing of the jaws prevents the accumulation of particles, and each chuck is equipped with a dust suction and slag suction port.

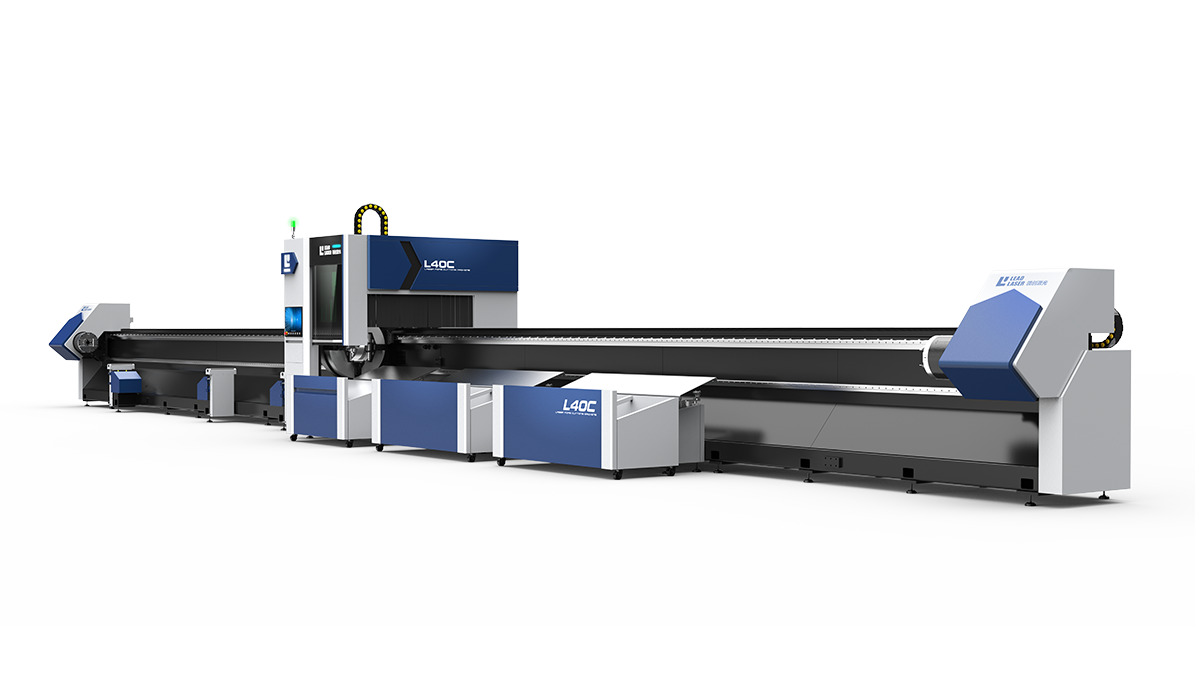

L40C technical features:

1. High-precision three-chuck clamping and cutting, the accuracy is better guaranteed

2. Zero tail cutting to achieve high utilization rate of pipes

3. Side hanging eccentric structure, convenient for loading

4. Intelligent blanking control to facilitate blanking of pipes of different lengths

5. The bed is welded by thick plate tubes, with built-in round tube support to enhance the rigidity of the bed

Golden Square VT-300

Golden Square VT-300

Golden Square VT-300

Performance characteristics of VT-300 electric servo CNC turret punch press:

. New electric servo CNC turret punch press.

. Larger turntable opening distance is more convenient for the production of special parts.

Standard 38-station turntable, more options for mold installation.

·The configuration of the mobile workbench makes the resistance of the plate movement smaller and the possibility of scratches is reduced to a lower level.

. Rack and pinion transmission, high speed, high efficiency and high stability.

AccurPress 516040

AccurPress 516040

Model: 516040 Bending width: 4200mm Hydraulic tonnage: 160 tons

This series adopts advanced electro-hydraulic synchronous closed-loop technology. The performance of the whole series has been improved, with high opening, long stroke, large throat, and a 35% increase in operating speed.

As a standard series, this series offers a wide range of supplies and a wide range of optional accessories.

AccurPress 510032

AccurPress 510032

Model: 510032 Bending width: 3200mm Tonnage: 100 tons

It adopts SVP (Servo Variable Pumping) oil-electric hybrid technology.

Low temperature, low noise, 40% energy saving, can significantly improve the performance of the machine tool and also have a good cost performance.

The machine has the characteristics of fast, precise, stable and low energy consumption.

Bending operation site:

AccurPress 506325

AccurPress 506325

Model: 506325 Bending width: 2500mm Tonnage: 63 tons

It adopts DSVP (Dual Servo Variable Pumping) oil-electric hybrid technology.

Low temperature, low noise, 60% energy saving, and greatly reduce the use of hydraulic oil.

The machine has the characteristics of high speed, high precision, stability and low energy consumption.

AccurPress S4012

AccurPress S4012

Model: S4012 Bending width: 1200mm Tonnage: 40 tons

The 40-ton 1.2-meter special design model is a star model for small parts processing.

It has the characteristics of flexibility, speed, precision and energy saving, and has a larger opening height and stroke than similar machines.

Compared with the traditional design of the same kind of horizontal bar and single shaft, the patented double-cylinder single-axis slider design, the machine can withstand a certain range of eccentric load bending.

Bending operation site:

Gold Square TPR8 20

Gold Square TPR8 20

Model: TPR8 20 Bending width: 2000mm Tonnage: 63 tons

CNC bending machine features:

. The fuselage is designed through finite element optimization to ensure high strength and high rigidity when the machine tool is in use.

Compared with the traditional CNC bending machine, the filling fluid flow, oil pump displacement, etc. are increased, and the Y-axis movement frequency is increased by about 25% compared with the mainstream bending machine in the market.

The high-frequency response proportional valve is used to ensure the high stability and high precision of the machine tool during high-speed operation.

The closed height, throat depth, slider stroke, etc. have been increased to facilitate bending and handling of large workpieces.

. The standard automatic mechanical deflection compensation system solves the influence of the deformation of the slider during the bending process on the quality of the workpiece.